| Stainless Steel Schedule Pipe | |

|---|---|

| Product size: | 4″, 5″, 6″, 7″, 8″, 9″, 10″ |

| Grade: | J4, J1, 304, 304L, 310, 316, 316L, 321, Inconel, Duplex Material |

| Thickness: | 1.00 to 5.00 mm |

Pipes for submersible pump & motor

| Standard Size |

Standard Size |

Standard Size |

Standard Size |

|---|---|---|---|

| 50.0 Dia | 0.2 | ||

| 69.8 Dia | 95.0 Dia | 139.0 Dia | 0.6 |

| 71.0 Dia | 101.5 Dia | 164.6 Dia | 0.9 |

| 80.0 Dia | 105.0 Dia | 172.0 Dia | 1.0 |

| 81.0 Dia | 108.8 Dia | 174.0 Dia | 1.2 |

| 81.5 Dia | 109.0 Dia | 176.0 Dia | 1.5 |

| 83.5 Dia | 109.5 Dia | 180.0 Dia | 2.0 |

| 84.5 Dia | 110.0 Dia | 181.0 Dia | 2.5 |

| 85.0 Dia | 115.8 Dia | 182.0 Dia | 3.0 |

| 85.5 Dia | 124.0 Dia | 183.5 Dia | 4.0 |

| 89.8 Dia | 124.8 Dia | 184.0 Dia | 5.0 |

| 92.0 Dia | 130.0 Dia | 185.5 Dia | 6.0 |

| 92.5 Dia | 135.0 Dia | ||

| 93.0 Dia | 137.0 Dia | ||

| 94.0 Dia | 138.0 Dia |

(V3, V4, V5, V6, V8 Submersible Pump pipe /Motor pipe).

Sizes & thickness is available as per your requirements

- We are also manufacturing 0.20 mm tubes for CAN motors in different diameter from 25 mm to 75 mm.

- Rings of 20 mm or other lengths are also our products.

- We also supply tubes with special grooves for circlip or with a ring insert, also with special welding for oil filled motors.

- Specialized in cut length as per parties requirements

Our Quality Standard

- Weld line testing at 20 kg.

- Length tolerance in 0.5 mm

- Ovality 0.4 mm

- Straightness 0.3mm max. For 500 mm length / 0.7mm for 1 meter lengths

- Finishing up to 1200 grit

We have full traceability system starting from raw material receipt, production division, and dispatch division along with billing section.

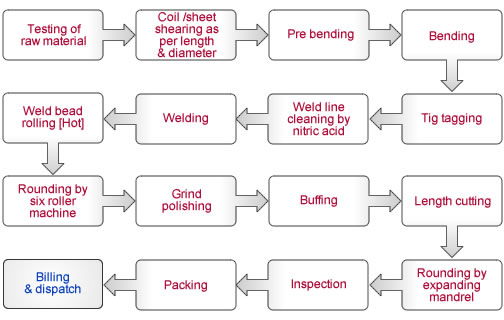

Process Flow Chart

- Testing of raw material

- Coil /sheet shearing as per length & diameter

- Pre bending

- Bending

- Tig tagging

- Weld line cleaning by nitric acid

- Welding

- Weld bead rolling [Hot]

- Rounding by six roller machine

- Grind polishing

- Buffing

- Length cutting

- Rounding by expanding mandrel

- Inspection

- Packing

- Billing & dispatch